95% of the masks on the market are of low quality, non-compliant with hygiene rules, and most importantly, they can only be used as a dust mask under the name of medical masks, and they do not have any bacteria / virus filtering feature.

The production of disposable 3-layer meltblown filter medical masks will be carried out in accordance with the standards by using an ultrasonic fully automatic production and packaging system. After the production has started, the necessary processes will be started to obtain CE-certificate and EN14683 certificates.

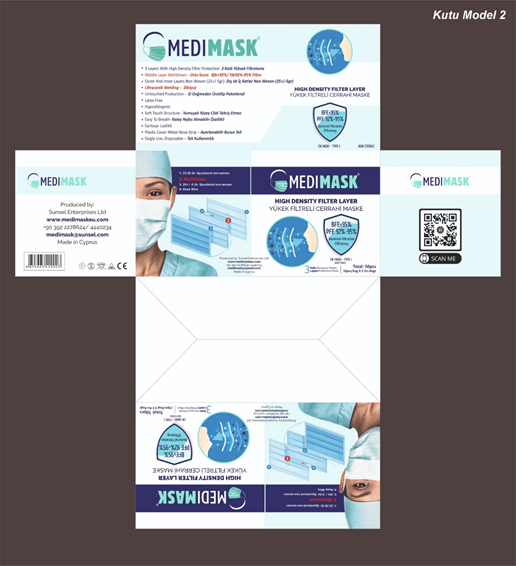

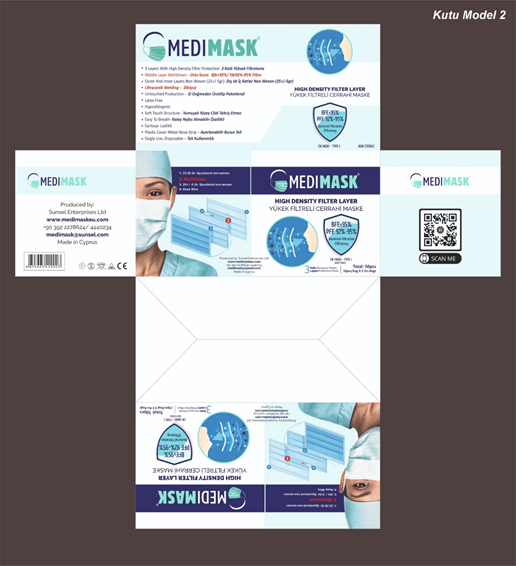

In this direction, we have decided to make this investment with the aim of offering the right product to our society and offering a reliable mask produced in a healthier environment and more protected against the current covit-19 virus. We have the goal of exporting this product not only to TRNC but also to Southern Cyprus and European countries. Therefore, our packages have been prepared in English and Turkish.

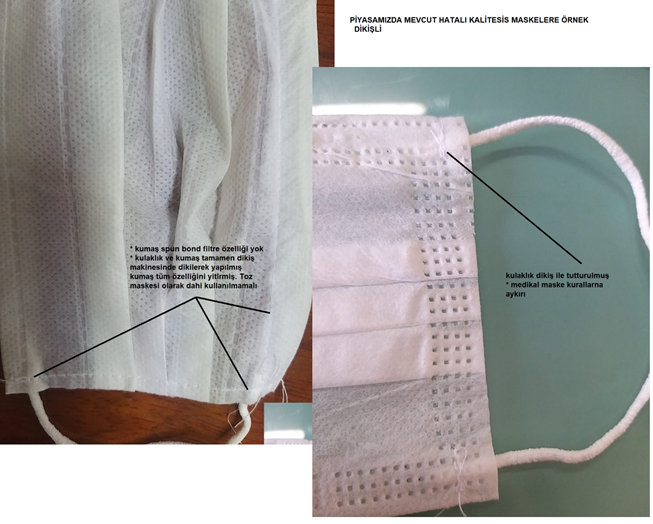

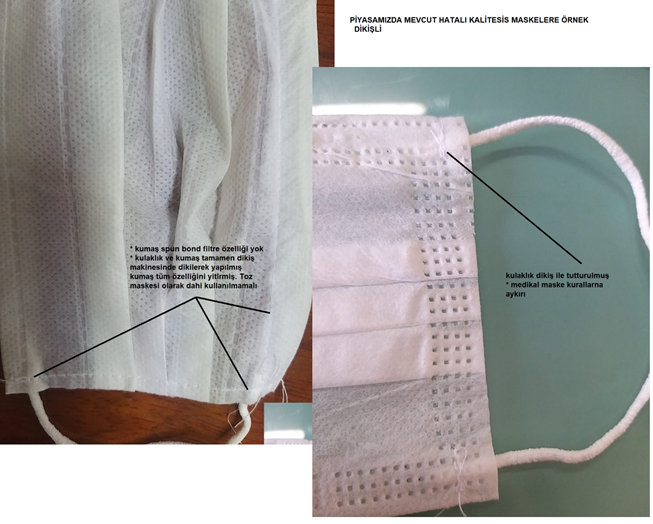

Examples of Unsuitable Masks Available in the Market are as follows

The masks in the market are 3 layers and the middle part is without filter. Also, the same fabric is used in the middle as the outer layers. These products can only be used as a dust mask. Absolutely against bacteria / viruses not protective. Unfortunately, our people are being deceived with masks right now.

Non-Ultrasonic Sewing Stitched Masks

Hand-sewn masks do not have a protective feature, and if the person who spikes does not comply with the hygiene rules, the person wearing this mask may also get sick.

Hygienic Unpackaged And Contact Open Masks

The vast majority of masks in our market are packaged hygienically. Masks packaged without bags are unhygienic due to unwanted contact on the shelf, on sale and on delivery.

The Right Medical Mask Example That Should Be: Sunsel Ent. Ltd. The Style Mask to Create

Our Medimask masks are 3-layered, non-woven SS bond fabric inside and outside, meltblown in the middle (nonwoven fabric that filters bacteria and viruses) is used.

Fully Automatic Ultrasonic Production and Packaging

Sunsel Enterprises LTD. With the machines and infrastructure to be set up, masks will be produced with the ultrasonic system without touching all hygiene conditions and the products will be packaged in bags in 10 pieces in the Flow Packetting device without human touch. It will then be put in boxes.

The place where the machines will be installed and manufactured will be separated by steel construction inside the building. The upper part of the room to be prepared for production will be closed and the necessary infrastructure arrangements will be made to ensure the necessary conditions, since the raw materials must be stored in a place with meltblown non-woven (bacteria and virus filter), without air circulation, without sunlight, and with controlled humidity.

The masks in the box will first be packaged in 10 pieces and packaged in 5 packages, ie 50 pieces, without human touch. 1 Box = 5 Packs = 50 Masks

Before our devices were loaded into the container, they were installed at the factory and trial production was made.

The picture below is an example. The visual example on the bags is shown below.